Digitization and transformation to Industry 4.0

MSME plays a very vital role in the development and GDP of India. MSME being at the root of the value addition chain, strong MSME sector will add up value to higher hierarchy in value chain and to manufacturing great products of improved quality. Its like a good quality seeds will result in good quality fruit in the end.

All around efforts are being undertaken by government and other agencies through different schemes and initiatives to increase strength of this MSME sector. This sector has its own issues, mainly because of its size.

The challenges faced by MSME ‘s are as follows..

- Attrition Rate

The pay scales to employees at MSME are at the lower levels as compared to industry level. Normally employees also use MSME as a launch pad for their careers. They look at it as either place of work because of other available options or to learn & gain some experience which will help them get a better opportunity in near future.

The employment duration varies from few months and 1 or 2 years depending on how fast the employee is able to get new opportunity. This creates a commitment and enabling issue. Many times it so happen, trainers find different employees in different training sessions and there is no continuity. Trainers have to start a fresh multiple times and the organization remain at the same knowledge and skill level even after multiple attempts.

- Access to new technologies

Overall technology in manufacturing industry is upgrading very fast and its adoption in MSME is very slow, thus creating a big gap between customer’s expectation and MSME ability. Large companies have adopted latest and emerging technologies but their suppliers are still operating at older technologies.

IT infrastructure in MSME is also limited to desktop computers or laptops only. High end servers and related software’s are not normally seen due its cost and high skilled human resources to maintain them.

- Access to advisors and consultants

MSME’s are not knowledge self-sufficient organizations due to rapidly changing technological scenario’s around and even in case prevailing standards or practices deployed in manufacturing, they would need advisors and consultants. Advisors and consultants are expensive services not affordable to MSME. Hand holding technological transformation are often a dream for MSME organization.

Customers need to take initiatives to provide knowledge and hand holding experience in technological up gradation of their suppliers.

- Investment Capability

This is root cause of all issues faced by MSME’s. MSME organizations expects returns on their investments in a very short time and do not have long time holding willingness. They may be willing to invest in high values equipment but investments for technology up gradations is on the last priority.

- Maintaining and sustaining high-tech initiatives

Some MSME organizations have taken initiatives but are not able maintain and sustain technology up gradation. The classic example is cluster approach adopted by many government agencies. Consultants services are available during the cluster period and during that period also the employees trained are changed. It becomes very difficult for cluster members organizations to sustain the new practices learned and most of them have come back the situations where they were few years ago.

Need for Technology Adoption

Manufacturing is changing every day. New technologies are emerging. We have not yet deployed Industry 4.0 and companies overseas are discussing Industry 5.0. Overseas companies are entering Indian market and are well equipped with latest technologies. These companies are way ahead of their Indian counterparts in terms of Quality, Cost and Delivery.

World is looking at Indian as Auto Manufacturing Hub and most of the companies in India supply auto components to many Automotive OEMs worldwide. These companies expects their suppliers to have adopted latest technology. If MSME does not adopt these latest technologies, then big world wide market could not catered.

MSME’s should get access to cost affordable, deployable, maintainable and sustainable technologies options in order to upgrade themselves with emerging technologies and improve performances on QUALITY, COST and DELIVERY.

MSME’s are undertaking lot of reactive measures in day to day operations which need to be converted to proactive measures to reduce non value adding activities and add value.

Most OEMs are multi national companies and they want their suppliers to have adopted international practices and standards along with latest technologies. The gap between customers’ expectations and suppliers readiness to meet them are increasing.

RIYO Cloud Suite for Quality, Productivity and Maintenance

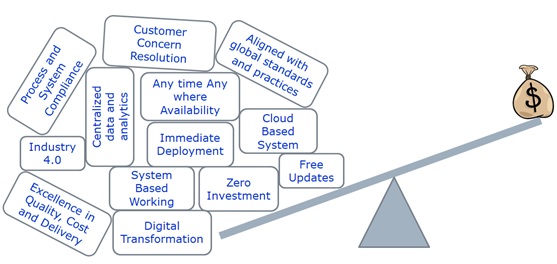

Understanding the challenges faced and current industry scenario, OpExWorks is offering a affordable, adoptable, maintainable and sustainable solution for MSME manufacturing companies.

These solutions include cloud based software for Quality Management, Productivity Management and Maintenance management. No IT infrastructure is needed to operate the software except one computer and internet connection.

Further these solutions are available on NIL one time cost and only on a pay per user per year subscription model which is again very much affordable. There are plan available to subscribe either for a year or 6 months or 3 months or even a 1 month depending on the priorities and requirements.

RIYO Mobile app

OpExWorks have also provided a RIYO mobile app which is available for download on Google Play store. The app connects the Senior management or Owners to plant operations in real time. The data entered or acquired at plant is visible to Senior managers or plant head in real time.

With lot of alerts and advanced data analytics, this RIYO app brings the entire plant operation in the pockets of senior managers and owners.

Affordable Machine to Mobile

Being robust and backed up by international brands like Mistubishi, the solution becomes maintainable and sustainable.

OpExWorks have also developed an affordable IoT solution providing Machine to Mobile connectivity for MSME’s. Based on the robust PLC’s manufactured by leading international brands like Mistubishi, OpExWorks have interfaced their RIYO suite with PLC’s for data acquisition from machines. This data collected from machines into a local computer is transferred onto cloud and made visible on mobile phone through RIYO app.

The one time hardware installation costs and recurring charges are way lower than what is offered in the industry on per machine per month basis.

Large base of Happy Customers

These solutions have been deployed in supply chain of Bajaj Auto Ltd. BAL is the world’s third largest motorcycle manufacturer. Their 50+ tier I vendors and 250+ Tier II vendors are using this platform for since last three years. There many other companies using these solutions for them and their suppliers.

Customer Engagements

Customers are also engaged on continuous basis through online or off line events. Recently, OpExWorks is organizing a completely paperless and online Kaizen contest for their customers. This will involve all customers on a common platform for continuous improvements and for scaling higher. Winners of this contest will be rewarded with recognition and cash prizes.

Free E Learning Portal on Lean Manufacturing

Considering the high attrition rates of engineers in MSME and unwillingness of MSME management to invest in educating their human resources in absence of long term work commitments, OpExWorks have launched a portal on Lean manufacturing which is made available for free to all manufacturing companies. Whether a manufacturing unit is using OpExWorks software or not, they can still enroll themselves on the Lean manufacturing portal and register for free e learning course.

About OpExWorks Solutions Pvt. Ltd.

OpExWorks Solutions Pvt. Ltd. is a software solutions company providing information technology and e learning support to manufacturing companies in their TPM, TQM, World Class Manufacturing and Lean manufacturing journey. We provide many solutions for achieving excellence in supply chain & supplier quality and implementation of Quality Management System, Plant Maintenance Management System and Operations Management systems at suppliers. Since last six years our solutions are in use at many large world class manufacturing companies

Web site : www.opexworks.com

OpExWorks Solutions was on the NASSCOM delegation to Silicon Valley “InnoTrek 2018”. This week long invite only delegation of selected 40 startups having global scalability potential from all over India was to introduce Indian startups to USA ecosystem for global expansion

For any further information on OpExWorks Solutions, Please write to info@opexworks.com, visit their web site www.opexworks.com or call on +91 8380069538.

Excellent Road map for MSME.It’s a sure shot way to success, detailing done in the areas guides you to adapt Tools of Industry management with almost no skill sets.

The end result is you experience is WoW moment’, Taking yu to. Industry 4 platform.

Good luck Team Opexworks !!! Your value addition will bring every user a professionaly satisfying life experience.What more you want !!

seems interesting..as Head of QA i face all the issues you have mentioned

send details …will check with suppliers

Thank you, we will get in touch with you shortly.

Great movement Pradeep saheb